From the quality of our raw materials supplier to our shipping partners, OSUNSHINE evaluates all partners and distributors to ensure that our services and ozone generators meet high quality standards. Key components are provided by internationally trusted manufacturers and inspected before being used. We train our inspection and quality control personnel to be experienced with more than 28 kinds of testing equipment to prevent any defective products from being shipped, making us a high quality ozone generator supplier.

1. SMT Machine

We use SMT machines and automatic CNC machines which have a speed of 0.04s/point and accuracy of 0.02mm, from the Japanese brand Fuji.

2. CNC Bending Machine

The CNC bending machine can process sheets with a length of 2500mm and a thickness of 6mm.

The ozone generator, after bending, has a ± 10 wire precision rate.

3. CNC Punch Press

4. CNC Machining Center

- CNC machining center realizes a range of processing functions.

- Machining precision of workpieces is ± 0.005mm.

A. Accessories assembly plant

The workshop includes generating tube assembly, circuit board testing, electrical performance testing as well as accessories packaging.

1) Generating tube assembly

- Assemble generating tubes of 3-57g and stainless steel tubes of 18-80g.

- The assembled ceramic tubular ozone generator.

2) Circuit board testing

Circuit board components are assembled according to product specifications.

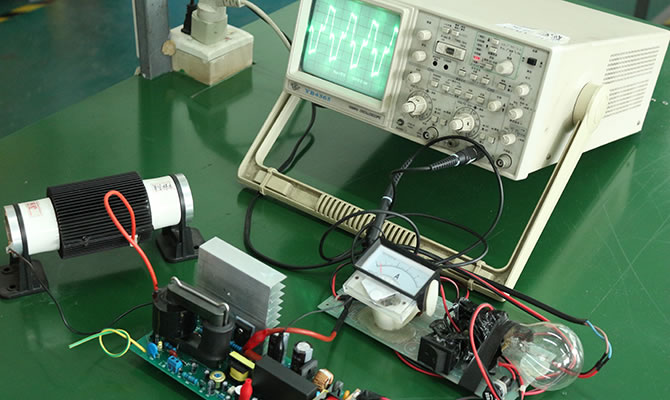

3) Electrical Performance Test

- The oscilloscope detects the power supply board frequency of the ceramic tubular ozone generator.

- The high voltage resistance tester detects the high pressure resistance safety performance of the machine and generating tube.

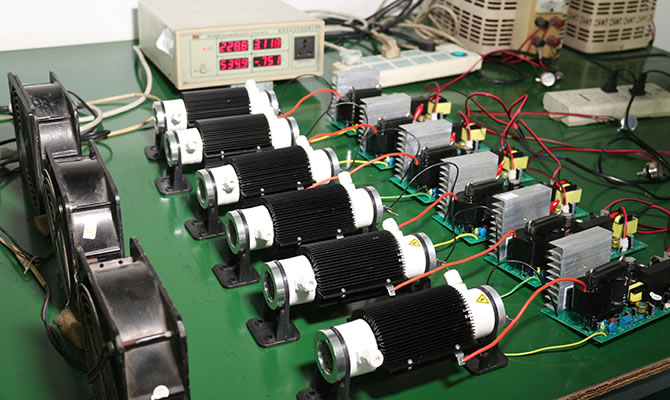

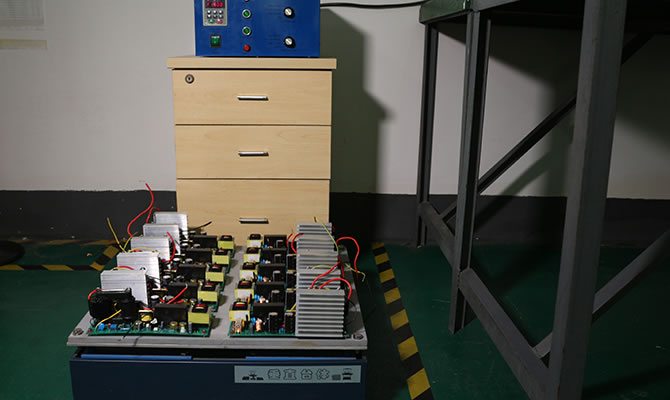

4) Spare Parts Aging Test

Connects the tube and the circuit board for aging test.

5) Spare Parts Packaging

Packaging designed according to product specifications, and padding prevents damage during transport.

6) Spare Parts Warehouse

The assembled semi-finished products will be placed in the warehouse after inspection.

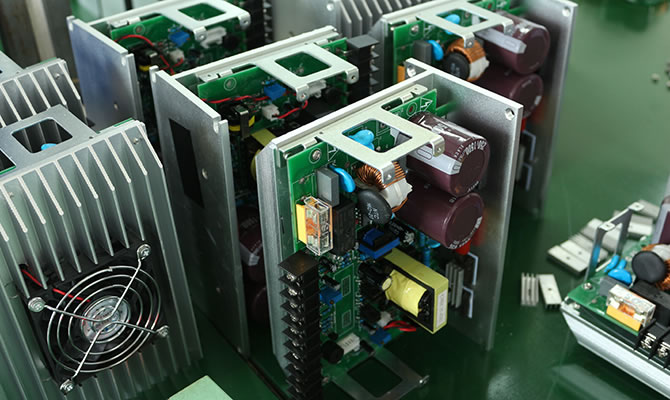

B. Intelligent power assembly

The power supply automatically alerts against faulty operation and water levels.

- Internal components of ozone smart power supply

- Input and output wiring area, lid can be closed

- Fans and corrugated heat sink design

- Regulation of control buttons

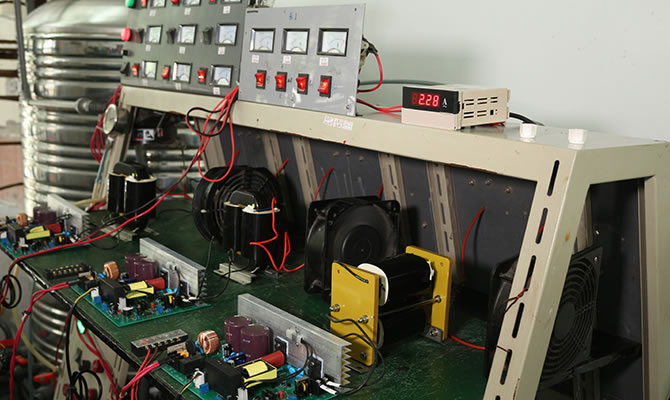

C. Circuit board aging test

Assembled circuit boards undergo an aging test.

D. Detecting vibration table

The assembled components placed on the vibration table for 30 minutes will be determined faulty or not.

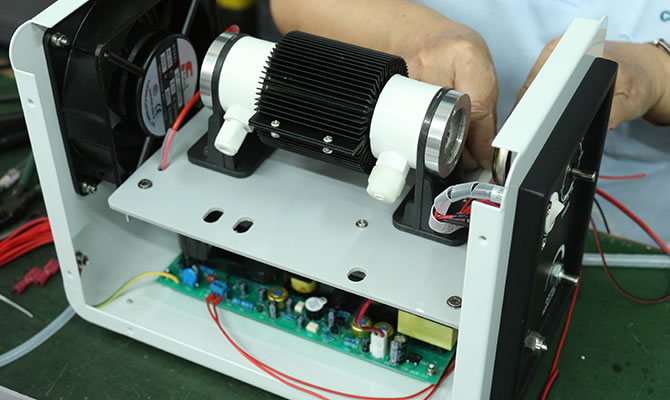

E. Small machine assembly plant

In this assembly plant, an experienced team assembles mini portable generators.

- Fix the qualified assembly components by screws, assembly the products according to the design structure.

- After assembly, products undergo 8-hour aging tests for stability and ozone uniformity.

-

After testing the product, the shell is installed.

- Packaging designed according to the specifications of the ozone generator. Cotton foam padding prevents damage during transport.

- Portable design with easy access handle

F. Large machine assembly plant

In this assembly plant, large ozone machines are assembled by an experienced team.

Finished KG large ozone equipment

Finished KG large ozone equipmentG. Ozone concentration detection for small machine

The lower the oxygen value, the higher the ozone concentration generated, and vice versa.

Oxygen display area

H. Ozone concentration detection

Detects the ozone concentration in large ozone machines and records the parameters.